... "I made a lot of progress today! I was going so fast that I almost passed a snail trapped in a puddle of molasses!"

Well, it seems that way. I started this oil change on November 8th and as I sit here in the quiet solitude of December 23rd, enjoying the last smidgen of calm before the holiday storm, I can reflect back on the intervening days and weeks and honestly wonder just why this is taking so daggone long. What it comes down to is a series of distractions combined with unforeseen delaying events. Distractions arising from holiday preparations and the seductive Siren call of the RV-12 project have certainly played a role, but the fiasco of the broken Subaru has played a part as well. And, truth be told, there was a bit of decision making to be done too.

As it stands today, the Subaru is repaired, the cowls are repaired, albeit without the final finishing step of applying paint to the repaired areas, and the decision has been made regarding how (and keep in mind that 'if' was a player as well) to replace the faulty attitude indicator.

The Subaru needed a new head gasket, but for a couple of reasons actually received two new head gaskets, a new timing belt, new spark plugs, and a new thermostat for the radiator. Plus fluids. Those aren't exactly cheap either, you know. Geographical challenges and some minor maintenance delays stretched the job out for a couple of weeks, but it's all done now and other than a lingering scent of baked antifreeze, everything seems to be working just fine. The car has over 80,000 miles on it and this is the first real maintenance it has needed, so I can't really complain.

The cowls are primered on the affected areas, but final painting will have to wait for the more conducive temperatures of Spring for final painting. Having been once burned, though, I'm naturally twice shy on the topic of hauling them out to my brother for painting. A pretty clear Karmic message has been sent: perhaps I should bite the bullet and learn how to operate the painting equipment I own. I have an air compressor and a Harbor Freight HVLP spray gun - I ought to see if I can learn how to use it.

In the meanwhile, I bought myself some time on the issue of the attitude indicator by removing the vacuum pump. Following my inimitable method of making big decisions (which is to muddle about making small decisions until I have painted myself into a corner), I spent quite a bit of time working with my mechanic to make sure every delaying tactic was both safe and useless.

The decision to be made was, of course, whether to replace the broken vacuum-powered, mechanical attitude gyro with a similar item, thereby running the risk of breaking another $700 gyro, or to upgrade to a solid state electronic model and slightly more than twice the cost. The higher cost option would normally have been the obvious solution because of the improved reliability combined with equally improved utility, but I can't help spicing up the decision making process by adding in the question of how long I will own this plane. But... a nicer panel is definitely an eye catcher at resale time too.

The state of play was a removed attitude indicator with its vacuum lines dangling in open air. The directional gyro had also been removed to allow access to the AI, so it too was dangling behind the panel. My initial thought was to reinstall the DG and fly without the AI until such time as I could decide on the long term course of action. My intuition told me that leaving the AIs vacuum limes sucking unfiltered air was a bad idea, and this was confirmed by the mechanic. He suggested plugging the lines with some plastic caps. Easy, right?

As I was lying on my back putting the caps on the lines, I realized that I had no stomach for putting the DG and all of the other associated pneumatic plumbing back into place just to remove it again when it came time to replace the AI, so I went ahead and completely removed it too. That left me with a bit of an issue: I could plug the vacuum lines for the DG too, but then the vacuum pump would be sucking on a pair of plugged lines. That didn't seem like a good thing.

At that point, I decided that the only real answer was to just remove everything and consider the question of what to put in the panel to be decided in favor of the electronic unit. And by everything, I mean the engine-mounted vacuum pump, the filter, and the tangle of hoses that connected it all. This decision, naturally, required another consult with the mechanic. Removing the vacuum pump would leave gaping wounds in the back of the engine and in the firewall. And there was also the question of how to remove the vacuum pump. It's located on the back of the engine in a position that precludes easy access to one of the four nuts that hold it on. In fact, in this era of pop rock bands having numeric names like Third Eye Blind, Five for Fighting, Maroon Five, and Avenged Sevenfold, I thought Three Nuts Easy would make a good name for an emerging group. To resolve the question of how to remove Fourth Nut Difficult, I again pestered the local mechanic.

"Well, we have a fancy wrench for that, but you could just use a mallet and a screwdriver."

Now, it may have been my imagination, but I'd swear he then adopted the waiting pose one gets when one has thrown out an answer and is expecting a "Huh??" in response. Sorry, though: it was not forthcoming. I knew exactly what he meant. Back in the Good Ole Days of my military servitude, I actually spent quite a bit of time working on airplanes. There were various infamous areas on both of the airplanes (I worked on SR-71s and RF-4Cs) I helped maintain that were either designed by diabolically clever sadists or egregiously incompetent engineers. In a word, they were what can only be described as inaccessible. While it was frowned upon, we had a Don't Ask, Don't Tell maintenance technique that involved placing the end of a flat blade screwdriver on the face of a nut (or in a groove on a cannon plug, for those of you that know what a cannon plug is) and tapping (that's a liberal stretching of the word 'tap' - in many cases 'hammering' would have been more appropriate) until it was loose. So, instead of the-secretly-hoped-for "Huh??" the reply was, "Oh, ok."

That left the issue of the gaping hole on the back of the engine (the problem of the hole in the firewall having been solved through the simple expedient of not removing the vacuum regulator that now benignly sits in the hole enjoying its forced retirement) which was cured with the placement of a charitably gifted metal blocking plate:

If nothing else comes of all this, it will now be orders of magnitude easier to change the oil filter. There's some irony involved in that if you think about how all of this transpired.

Plus, the plane will be just a wee bit lighter. Here's all of the stuff that I don't have to carry around anymore:

And what do you do with a broken old attitude indicator? If you're the curious type, you do this:

Oh, don't criticize me. You know you've always want to see the innards of one of these things. Besides, it will make a good desk-oration at work.

So, what's going to eventually go into the panel? One of these:

And why 'eventually'? Because the acquisition price of one of those little guys is right here:

That gasket is the one that was allowing pressurized gas from the combustion chamber(s) to over-pressurize the radiator, thus forcing coolant out of the radiator and onto the rest of the engine. The stuff in the box is all of the expensive junk that was protecting the corrupt gasket.

It'll take a little time to recover from that, Xmas, and the property tax bill that's due in January. Still, it's good to have the decision finally made.

Wednesday, December 23, 2009

Sunday, December 06, 2009

In a tight spot in the RV-6

Remember this?

That's my broken attitude indicator. I decided that since the weather today was offering a balmy 30F temperature to work in and the airplane is still broken while waiting for the cowls to return from the paint shop, I'd go ahead and remove the broken attitude indicator. I still don't know if I'm going to replace it, but I have a new argument in the "against" column: it took two and a half hours to remove it. And that's the easy part! I'm not proud of the language that it took to get the old one out (nor am I ashamed of it - I was provoked!) but I'm preemptively appalled at the colorful linguistics that will be surely be required to replace it.

That and the $500 for a new one.

Still, there's resale value to consider.

Decisions, decisions.

But I can't stress enough just how horrible it is to work behind the panel on an RV-6. Cramming myself into the tiny space down by the rudder pedals to reach up behind the panel makes even a small-ish guy like me feel as big as an NFL offensive lineman. That's not nearly as cool as I had thought it would be. In fact, it sucks.

Maybe I'll violate the code and hire someone to do it.

Decisions, decisions.

That's my broken attitude indicator. I decided that since the weather today was offering a balmy 30F temperature to work in and the airplane is still broken while waiting for the cowls to return from the paint shop, I'd go ahead and remove the broken attitude indicator. I still don't know if I'm going to replace it, but I have a new argument in the "against" column: it took two and a half hours to remove it. And that's the easy part! I'm not proud of the language that it took to get the old one out (nor am I ashamed of it - I was provoked!) but I'm preemptively appalled at the colorful linguistics that will be surely be required to replace it.

That and the $500 for a new one.

Still, there's resale value to consider.

Decisions, decisions.

But I can't stress enough just how horrible it is to work behind the panel on an RV-6. Cramming myself into the tiny space down by the rudder pedals to reach up behind the panel makes even a small-ish guy like me feel as big as an NFL offensive lineman. That's not nearly as cool as I had thought it would be. In fact, it sucks.

Maybe I'll violate the code and hire someone to do it.

Decisions, decisions.

Worst. Oil Change. Ever.

It felt like it should be the final stretch of getting the saga of the oil change completed. The cowls have been repaired, test fitted, and readied for painting. Once painted, we're finally only a 15 minute installation on the plane from being done. Bet here's the thing about the final stretch (and you pay very close attention to the next race you watch to test the veracity of this observation if you don't believe me): it's a horrible time to change drivers.

The thing is, I have neither the equipment nor the expertise to paint the cowls. Nor the wheel pants, which is why they've been painted with rattle can primer for the last three years. Fortunately, I'm related to the Chief Mechanic at the 8105 Repair Shop and he knows how to paint. I figured I'd just drive the cowls out to his shop and have him paint them up. How hard could that be? For me, I mean. Drive 'em out, drop 'em off, and pick them up when they're done. Piece of cake!

The cowls and wheel pants took up every cubic inch of free space in my suited-more-for-hauling-groceries Subaru Forester, leaving room only for a single pilot. No problem - this was an out and back trip and not necessarily an opportunity to get some road miles for co-pilot Egg. Going solo lets me set the schedule, so I pulled chocks little before 0800. It's an easy drive that early in the morning and the Across the Universe CDs (highly recommended) made for a relaxed trip.

Well, until I got there, anyway.

As I pulled to a stop in the visitor parking at the Schmetterling Aviation World Headquarters (which is conveniently adjacent to one of their other holdings, the 8105 Racing shop, which is itself co-located with the 8105 Repair Shop that was going to do the cowl painting), the overbearingly rancid sweet smell of antifreeze emanating from the front regions of the normally ultra-reliable Subie hinted that there may be something amiss in the Department of Automotive Propulsive Force, or "the engine" as it's called in the vernacular. More specifically, in the Thermal Protection Unit.

There is an age old ritual for situations like this that we've all inherited through either or both of parental example or aging Hollywood movies: we raise the hood. Which ritual has become increasingly difficult to perform over the intervening years with the introduction of multiple release latches located (hidden?) both inside and outside of the passenger compartment. Needlessly complex, in my considered opinion. And deliberate besides. It's the automotive designer's way of telling us that we ought just stay the hell outta there and leave it all to the specialists. Always the contrarion and as diabolically clever as a monkey, I defeated their defenses and opened the door to the vault.

It was ugly. The overflow bucket from the radiator was frothing like a rabid Pit Bull and the rest of the engine was covered in spots of flung Pit Bull spittle. Your name doesn't have to be Shelby to figure out that it really isn't supposed to look like that. Or smell like it, for that matter. It smelled like a gallon of Log Cabin faux-syrup had exploded onto a burned skunk. Trust me, that's not a taste sensation we're going to be seeing in the snack aisle at the 7-11 anytime soon. Peee-yooooo.

Well, I was headed to the shop anyway, right?

The news at the shop? Pretty good, but only in aspects unrelated to the car. That particular piece of news was pretty bad. Ten Bills O' Bad:

"Blown head gasket. Might was well replace both while we're in there. And the timing belt, too. When can I start?"

Well, there's the whole question of transportation home, right? I had always thought this kind of thing would happen with the airplane. Fly somewhere, land, find out that we're not flying back. Rent a car, drive home. Sell airplane where it sits. Well, no, probably not that last part, although I can easily imagine being tempted at this point in the never-ending oil change. In this case, I was able to borrow the CEO's personal sports car for the week. I gotta tell you, it's a very nice ride. I still have to look at the owners manual to verify this, but I'd swear that the CD player automatically reduces its volume when you slow from highway speeds (which are limited only by the speed rating of the tires) to a stop at the exit. Incredible!

While at the shop I also retrieved my Walther P-38 that I had asked the Chief Mechanic to take a look at. It was jamming on every second or third round, and that takes a lot of the fun out of shooting it. Although... it probably helps control ammunition expenses. Either way, the gun needed some work.

It looked like a brand new gun. I don't think it has been that clean since it rolled off of the assembly line 50+ years ago. And the jamming problem had reportedly been resolved. I was anxious to finally shoot it with it functioning correctly, so I asked if there was a target handy that I could toss a few shots at.

"No, not that mangy cat, please. An inanimate target would serve better. Not through any love of cats, mind you. I just figure a stationary target will better suit my limited aiming abilities."

Because, you see, I'm a horrible shot. Not so with the Chief Mechanic, who's quite good at it. Once again pointing out the vagaries of genetics. This is the nature of the normal love/hate relationship between siblongs, I imagine.

"Here, I'll take this brick down to the field. You stay up here on the driveway and take a few shots at it," was his suggestion.

Thinking that surely (stop calling me Shirley) he was yanking my chain, I follwed him halfway down the hill.

"What are you doing down here??"

"I thought I might like to shoot at it from somewhere where I could actually see it," I replied. Quite truthfully, too.

Five shots, five misses.

Great glee from the audience.

A "you do it" challenge from me.

One shot. Nothing left of the brick but red dust. Roughly the same left of my self esteem. Oh, and from the top of the hill, naturally.

Like I said: love, hate.

The thing is, I have neither the equipment nor the expertise to paint the cowls. Nor the wheel pants, which is why they've been painted with rattle can primer for the last three years. Fortunately, I'm related to the Chief Mechanic at the 8105 Repair Shop and he knows how to paint. I figured I'd just drive the cowls out to his shop and have him paint them up. How hard could that be? For me, I mean. Drive 'em out, drop 'em off, and pick them up when they're done. Piece of cake!

The cowls and wheel pants took up every cubic inch of free space in my suited-more-for-hauling-groceries Subaru Forester, leaving room only for a single pilot. No problem - this was an out and back trip and not necessarily an opportunity to get some road miles for co-pilot Egg. Going solo lets me set the schedule, so I pulled chocks little before 0800. It's an easy drive that early in the morning and the Across the Universe CDs (highly recommended) made for a relaxed trip.

Well, until I got there, anyway.

As I pulled to a stop in the visitor parking at the Schmetterling Aviation World Headquarters (which is conveniently adjacent to one of their other holdings, the 8105 Racing shop, which is itself co-located with the 8105 Repair Shop that was going to do the cowl painting), the overbearingly rancid sweet smell of antifreeze emanating from the front regions of the normally ultra-reliable Subie hinted that there may be something amiss in the Department of Automotive Propulsive Force, or "the engine" as it's called in the vernacular. More specifically, in the Thermal Protection Unit.

There is an age old ritual for situations like this that we've all inherited through either or both of parental example or aging Hollywood movies: we raise the hood. Which ritual has become increasingly difficult to perform over the intervening years with the introduction of multiple release latches located (hidden?) both inside and outside of the passenger compartment. Needlessly complex, in my considered opinion. And deliberate besides. It's the automotive designer's way of telling us that we ought just stay the hell outta there and leave it all to the specialists. Always the contrarion and as diabolically clever as a monkey, I defeated their defenses and opened the door to the vault.

It was ugly. The overflow bucket from the radiator was frothing like a rabid Pit Bull and the rest of the engine was covered in spots of flung Pit Bull spittle. Your name doesn't have to be Shelby to figure out that it really isn't supposed to look like that. Or smell like it, for that matter. It smelled like a gallon of Log Cabin faux-syrup had exploded onto a burned skunk. Trust me, that's not a taste sensation we're going to be seeing in the snack aisle at the 7-11 anytime soon. Peee-yooooo.

Well, I was headed to the shop anyway, right?

The news at the shop? Pretty good, but only in aspects unrelated to the car. That particular piece of news was pretty bad. Ten Bills O' Bad:

"Blown head gasket. Might was well replace both while we're in there. And the timing belt, too. When can I start?"

Well, there's the whole question of transportation home, right? I had always thought this kind of thing would happen with the airplane. Fly somewhere, land, find out that we're not flying back. Rent a car, drive home. Sell airplane where it sits. Well, no, probably not that last part, although I can easily imagine being tempted at this point in the never-ending oil change. In this case, I was able to borrow the CEO's personal sports car for the week. I gotta tell you, it's a very nice ride. I still have to look at the owners manual to verify this, but I'd swear that the CD player automatically reduces its volume when you slow from highway speeds (which are limited only by the speed rating of the tires) to a stop at the exit. Incredible!

While at the shop I also retrieved my Walther P-38 that I had asked the Chief Mechanic to take a look at. It was jamming on every second or third round, and that takes a lot of the fun out of shooting it. Although... it probably helps control ammunition expenses. Either way, the gun needed some work.

It looked like a brand new gun. I don't think it has been that clean since it rolled off of the assembly line 50+ years ago. And the jamming problem had reportedly been resolved. I was anxious to finally shoot it with it functioning correctly, so I asked if there was a target handy that I could toss a few shots at.

"No, not that mangy cat, please. An inanimate target would serve better. Not through any love of cats, mind you. I just figure a stationary target will better suit my limited aiming abilities."

Because, you see, I'm a horrible shot. Not so with the Chief Mechanic, who's quite good at it. Once again pointing out the vagaries of genetics. This is the nature of the normal love/hate relationship between siblongs, I imagine.

"Here, I'll take this brick down to the field. You stay up here on the driveway and take a few shots at it," was his suggestion.

Thinking that surely (stop calling me Shirley) he was yanking my chain, I follwed him halfway down the hill.

"What are you doing down here??"

"I thought I might like to shoot at it from somewhere where I could actually see it," I replied. Quite truthfully, too.

Five shots, five misses.

Great glee from the audience.

A "you do it" challenge from me.

One shot. Nothing left of the brick but red dust. Roughly the same left of my self esteem. Oh, and from the top of the hill, naturally.

Like I said: love, hate.

Wednesday, December 02, 2009

The month long oil change...

... still is not done. But as of tonight it is just a little bit closer. Tonight I test fit the repaired cowls and they fit!

Over the last few days, I've been working on finishing the refill of the previous rivet holes. That involved grinding off excess epoxy with a Dremel tool, adding a fill layer of epoxy thickened with filler, and sanding off most of that layer to leave a smooth finish. It actually looked pretty good:

Yesterday I countersunk the rivet holes for the flush rivets that would be used to hold the new hinge strip in place. That turned out to be surprisingly easy to do, but even more surprisingly hard to do well. The problem turned out to be that it is so easy to cut the countersink hole in the fiberglass even by manually turning the bit that it is also disconcertingly easy to drill too deep. I didn't know that, of course, until I had squeezed in all of the new rivets and sprayed on a coat of primer.

Primer is like the mean mother-in-law of paint: it revels in ostentatiously demonstrating your weaknesses. I swear, that row of rivets looked so bad that it was almost like a satirical parodization* of British dental work. Having had a night to get over the initial chagrin, though, I think a little bondo or a few thick coats of paint will serve to hide my shame. Which, after all, is all you can ever really ask for from life, right?

My biggest worry was that nothing would line up when it came time to mount the cowls to the plane. Co-pilot Rick drove down to the airport in the crappy wet weather we're currently having (the weather can sense that I might soon have a flyable airplane and wants to get a few early kicks in) to help me to do the test install. Everything fit just fine, and in certain aspects the cowls went on easier than ever before. That was a huge relief!

The cowls are back off of the airplane now, awaiting a trip to the paint shop.

* not a real word, at least according to Google, but it ought to be!

Over the last few days, I've been working on finishing the refill of the previous rivet holes. That involved grinding off excess epoxy with a Dremel tool, adding a fill layer of epoxy thickened with filler, and sanding off most of that layer to leave a smooth finish. It actually looked pretty good:

Yesterday I countersunk the rivet holes for the flush rivets that would be used to hold the new hinge strip in place. That turned out to be surprisingly easy to do, but even more surprisingly hard to do well. The problem turned out to be that it is so easy to cut the countersink hole in the fiberglass even by manually turning the bit that it is also disconcertingly easy to drill too deep. I didn't know that, of course, until I had squeezed in all of the new rivets and sprayed on a coat of primer.

Primer is like the mean mother-in-law of paint: it revels in ostentatiously demonstrating your weaknesses. I swear, that row of rivets looked so bad that it was almost like a satirical parodization* of British dental work. Having had a night to get over the initial chagrin, though, I think a little bondo or a few thick coats of paint will serve to hide my shame. Which, after all, is all you can ever really ask for from life, right?

My biggest worry was that nothing would line up when it came time to mount the cowls to the plane. Co-pilot Rick drove down to the airport in the crappy wet weather we're currently having (the weather can sense that I might soon have a flyable airplane and wants to get a few early kicks in) to help me to do the test install. Everything fit just fine, and in certain aspects the cowls went on easier than ever before. That was a huge relief!

The cowls are back off of the airplane now, awaiting a trip to the paint shop.

* not a real word, at least according to Google, but it ought to be!

Saturday, November 28, 2009

Sunny and 50 today

Thus proving that my weather talisman is still demonstrating a preternatural efficacy in preventing the type of weather that wouldn't frustrate me. I'm still waiting for the rivets I need to attach the new hinge piece. There was still a little prep work to do, so I knocked that out this morning. I borrowed Co-pilot Rick's Dremel tool to grind down the bumps left by my overly zealous application of epoxy to fill the old holes. The worked great, but there was no way I was going to get a nice, smooth finish after doing that. I still have quite a bit of epoxy filler left over from filling the pinholes on the new wheel pants I installed four years ago, so I mixed up a batch of paste and smoothed it along the edge. Was that later cures, I'll sand it smooth and put a skim coat of unadulterated epoxy on top of it to protect it.

Then it should just be a matter of countersinking the holes for the rivets and putting it all together. For now it will have to get by with a coat of rattle can enamel paint. It will never look as good as it used to, I'm afraid.

Then it should just be a matter of countersinking the holes for the rivets and putting it all together. For now it will have to get by with a coat of rattle can enamel paint. It will never look as good as it used to, I'm afraid.

Sunday, November 22, 2009

Cowl Update

The halves are joined!

Now I have to let the epoxy that I used to fill the holes cure for a few more hours, then figure out a way to drill the new holes. I want to drill from the inside out, but that will make it hard to hot the old holes. There's no requirement to do so, of course, but it seems like it would be cleaner looking. I don't want to go from the outside in because it will push the hinge away and make it next to impossible to drill a round, accurately placed hold. Maybe I could do just a few inside outs and count on clecos to hold the hinge in place for the outside in drilling, but I'm dubious on a favorable prognosis.

There also quite a bit of epoxy that needs to be cleaned up on the holes, and the original installation of the hinge had 1/4" or so holes drilled in it and epoxy used to help the rivets hold it in place. So.... good progress, but plenty more to do yet.

Now I have to let the epoxy that I used to fill the holes cure for a few more hours, then figure out a way to drill the new holes. I want to drill from the inside out, but that will make it hard to hot the old holes. There's no requirement to do so, of course, but it seems like it would be cleaner looking. I don't want to go from the outside in because it will push the hinge away and make it next to impossible to drill a round, accurately placed hold. Maybe I could do just a few inside outs and count on clecos to hold the hinge in place for the outside in drilling, but I'm dubious on a favorable prognosis.

There also quite a bit of epoxy that needs to be cleaned up on the holes, and the original installation of the hinge had 1/4" or so holes drilled in it and epoxy used to help the rivets hold it in place. So.... good progress, but plenty more to do yet.

Saturday, November 21, 2009

Taunted by the weather

It would have been a great day to fly. That's all I can say about it; any more than that will require to think about how unseasonably beautiful our weather was today and likely will also be tomorrow. It's like getting a two day reprieve from being sent to a Siberian gulag but having to spend it fixing your plumbing. In may case, it is still the cowl that's keeping me grounded.

I started working on it this morning, though. The first thing that had to be done was the grinding away of the old epoxy that had apparently been used to aid the rivets in holding the hinge strip to the cowl. This step was quite easy, mostly due to a convenient tool crossover. I used the orbital sander that played such an integral role in the building of the kayak:

I also had to drill out the rivets holding in the remaining piece of yet another broken hinge. It's bad enough that I have no idea how this one got broken, but I also have no idea how it got broken this badly:

On the plus side, it was far easier to drill out the rivets from the inside out than it had been to do it from the outside in like I had to do with the other hinge:

Not that it matters because they're going to get filled with epoxy anyway, but the holes got far less elongated:

In yet another beneficent crossover, leftover materials from the kayak were already on hand for the filling of the old holes with new epoxy:

The pumps on the epoxy containers hadn't been exercised for a couple of years so I had to purge them, clean them, and re-prime them before dosing out a bit of epoxy to suck into a syringe. My first idea was to clamp the new hinge in place and use it to hold the epoxy in the holes:

That didn't work as well as I had hoped it would so I had to remove the hinge and try masking tape instead:

That seemed to work a lot better. Now it all needs to sit overnight curing.

I'll check on it second thing in the morning. What will I do first thing in the morning? Well, more than likely I'll be outside shaking my fist at a tauntingly blue sky.

I started working on it this morning, though. The first thing that had to be done was the grinding away of the old epoxy that had apparently been used to aid the rivets in holding the hinge strip to the cowl. This step was quite easy, mostly due to a convenient tool crossover. I used the orbital sander that played such an integral role in the building of the kayak:

I also had to drill out the rivets holding in the remaining piece of yet another broken hinge. It's bad enough that I have no idea how this one got broken, but I also have no idea how it got broken this badly:

On the plus side, it was far easier to drill out the rivets from the inside out than it had been to do it from the outside in like I had to do with the other hinge:

Not that it matters because they're going to get filled with epoxy anyway, but the holes got far less elongated:

In yet another beneficent crossover, leftover materials from the kayak were already on hand for the filling of the old holes with new epoxy:

The pumps on the epoxy containers hadn't been exercised for a couple of years so I had to purge them, clean them, and re-prime them before dosing out a bit of epoxy to suck into a syringe. My first idea was to clamp the new hinge in place and use it to hold the epoxy in the holes:

That didn't work as well as I had hoped it would so I had to remove the hinge and try masking tape instead:

That seemed to work a lot better. Now it all needs to sit overnight curing.

I'll check on it second thing in the morning. What will I do first thing in the morning? Well, more than likely I'll be outside shaking my fist at a tauntingly blue sky.

Monday, November 16, 2009

At least the oil is drained

It was a beautiful weekend with weather as foreign to an Ohio November as parrot meat to a polar bear. Temps hovering near 70 and clear, calm skies. So where was I? Still waiting for new hinge strip material to fix Papa's cowls.

With weather that nice, though, any time spent at the hangar is good time. I went out and finished draining the oil out of the oil filter. That's typically a messy job, but with time to spare I was able to devote sufficient time to the task to get it done without spilling a single drop. That's not as easy as it may sound. To remove the filter without spilling any oil down the back of the engine or the front of the firewall is a tightly choreographed effort involving an electric drill, a modified water bottle, and a lot of rags. It's worth the effort, though, because any oil spilled will eventually end up spread down the belly of the airplane. It is NO fun at all cleaning the belly, no matter what the weather.

While waiting for the oil to drain, I removed the wheel pants. That too is a persnickety job that I try to avoid whenever possible, but the tires are soon (assuming I ever fly again) going to be showing thread, at which point they will have to be replaced. Besides that, the annual inspection will be due in just a couple of months, so I figured I pull the wheel pants off while the hangar floor was at least somewhat warm and just leave them off until after the annual.

The rest of the weekend was spent doing various winter preparation chores and working on the RV-12. It's funny that the RV-12 project was intended to fill the time in the gawd-awful winter months when it's too cold and/or nasty to go outside, but I enjoy the "work" so much that I spent most of a beautiful weekend in the basement building a stabilator. I only went outside long enough to go to Lowes to buy a snow blower. With the weather being what it was, there wasn't much competition to buy a snow blower; those procrastinators will find that I got there before them.

Naturally, they will get the last laugh when it doesn't snow at all this year.

With weather that nice, though, any time spent at the hangar is good time. I went out and finished draining the oil out of the oil filter. That's typically a messy job, but with time to spare I was able to devote sufficient time to the task to get it done without spilling a single drop. That's not as easy as it may sound. To remove the filter without spilling any oil down the back of the engine or the front of the firewall is a tightly choreographed effort involving an electric drill, a modified water bottle, and a lot of rags. It's worth the effort, though, because any oil spilled will eventually end up spread down the belly of the airplane. It is NO fun at all cleaning the belly, no matter what the weather.

While waiting for the oil to drain, I removed the wheel pants. That too is a persnickety job that I try to avoid whenever possible, but the tires are soon (assuming I ever fly again) going to be showing thread, at which point they will have to be replaced. Besides that, the annual inspection will be due in just a couple of months, so I figured I pull the wheel pants off while the hangar floor was at least somewhat warm and just leave them off until after the annual.

The rest of the weekend was spent doing various winter preparation chores and working on the RV-12. It's funny that the RV-12 project was intended to fill the time in the gawd-awful winter months when it's too cold and/or nasty to go outside, but I enjoy the "work" so much that I spent most of a beautiful weekend in the basement building a stabilator. I only went outside long enough to go to Lowes to buy a snow blower. With the weather being what it was, there wasn't much competition to buy a snow blower; those procrastinators will find that I got there before them.

Naturally, they will get the last laugh when it doesn't snow at all this year.

Wednesday, November 11, 2009

Nothing ever gets easier, either

After stressing about it for a few days and gathering opinions as to what to do from other RV owners, it came down to the fact that the only way to get the cowl off of Papa would be to drill out the rivets that hold the hinge in place. Naturally, as this would be the most destructive and invasive way to do it, I was very reluctant to do it. After a period of energetic loin girding, I grabbed the drill and a #41 bit and went at it. An hour (and a few choice cuts on my fingers) later, the cowl was off. And, I'm sorry to say, somewhat maimed. I knew that was a very real possibility, though, so selected the top cowl to be sacrificed since it's easier to transport to a more comfortable location to be worked on.

It turns out that it's harder to drill a rivet out of fiberglass than it is to drill one out of aluminum. I'm sure this is almost universally true, but it becomes even more true if you can't really see exactly where the rivet is. If it was under a thick coat of paint, like. Adds to the challenge, that. Some of the rivets came out peacefully, others barricaded themselves in and hoped I wouldn't call in the SWAT team. They underestimated my resolve, probably unaware of the girded loins that I was bringing to the battle. And a #41 drill bit.

The difficulty in drilling out the rivets in fiberglass is that they are surrounded by a much softer, pliant material. If the bit got even the least bit off the center of the rivet, it would take the path of lesser resistance and slice off into the fiberglass. There is no silver lining in that cloud. Not only does it create a messy, large hole in the fiberglass that will have to be fixed (somehow - not quite sure how yet, and my loins are at this point quite ungirded), it also leaves enough rivet in place to maintain a strangle hold on the hinge. Oh, and it also leaves a very sharp edge, perfect for lacerating fingertips if one was careless enough to try to wipe away what looked like paint and/or metal shavings. Let's just say that if one were to do that, one would later realize just how deep those cuts were when one was slicing onions for dinner. Or trying to type a blog post, for that matter.

As it stands today, the cowl has bigger holes in it than our national budget and the hinge strip is as ruined as Congressional credibility. (Sorry, I had the radio news on - it has the effect on me) I think the cowl can be repaired by filling the holes with epoxy thickened with microballoons, but the hinge will have to be replaced. The hinge material is not expensive, but the job of matching and drilling new holes so that the top cowl will line up with the bottom has me worried. I'll stew on that for a few days; something will come to me. It always does.

It turns out that it's harder to drill a rivet out of fiberglass than it is to drill one out of aluminum. I'm sure this is almost universally true, but it becomes even more true if you can't really see exactly where the rivet is. If it was under a thick coat of paint, like. Adds to the challenge, that. Some of the rivets came out peacefully, others barricaded themselves in and hoped I wouldn't call in the SWAT team. They underestimated my resolve, probably unaware of the girded loins that I was bringing to the battle. And a #41 drill bit.

The difficulty in drilling out the rivets in fiberglass is that they are surrounded by a much softer, pliant material. If the bit got even the least bit off the center of the rivet, it would take the path of lesser resistance and slice off into the fiberglass. There is no silver lining in that cloud. Not only does it create a messy, large hole in the fiberglass that will have to be fixed (somehow - not quite sure how yet, and my loins are at this point quite ungirded), it also leaves enough rivet in place to maintain a strangle hold on the hinge. Oh, and it also leaves a very sharp edge, perfect for lacerating fingertips if one was careless enough to try to wipe away what looked like paint and/or metal shavings. Let's just say that if one were to do that, one would later realize just how deep those cuts were when one was slicing onions for dinner. Or trying to type a blog post, for that matter.

As it stands today, the cowl has bigger holes in it than our national budget and the hinge strip is as ruined as Congressional credibility. (Sorry, I had the radio news on - it has the effect on me) I think the cowl can be repaired by filling the holes with epoxy thickened with microballoons, but the hinge will have to be replaced. The hinge material is not expensive, but the job of matching and drilling new holes so that the top cowl will line up with the bottom has me worried. I'll stew on that for a few days; something will come to me. It always does.

Sunday, November 08, 2009

Nothing is ever easy

The weather is fantastic, particularly considering that we're into November and there's no longer any point in living in denial as to what's just around the corner.

I thought it would be a good day to take Co-pilot Egg for a short plane ride out to MadCo and environs for a breath of fresh air and a load of new fuel for Papa, then drain the oil for the last oil change of the year.

There's nothing like a plane ride to bring out the natural beauty of a teen aged girl:

Or, you know.... not.

The winds at MadCo were 13 gusting 17, straight out of the south. The only way to have gotten that cross wind any crosser would have been to insult its mother. The landing went OK - I held a bunch of left bank into it and a boot full of right rudder to keep us on the straight and narrow. I thought for a second in the flare that we were going to smack the runway like a spoiled 3 year old at Wal-Mart, but I timed it perfectly and rubbed it on with an unexpected greaser.

I bounced it back at Bolton. Just to keep my streak going, of course.

The Co-pilot was of great assistance when it came time to push the fuel-bloated plane back into the hangar:

While she relaxed, I started to remove the cowls. I didn't, however, finish removing the cowls. If you could pick the absolutely worst place for the long hinge wire that runs along the seam where the top and bottom cowls meet to break, it would be right at the point where the wire would be flush with the first hoop. If that were to happen, you'd have no way in the world short of drilling out all of the rivets that hold the hinge in place on the cowl to get the cowls apart.

Here's what it would look like:

Ask me how I know.

Oh well, it's just one more thing on the to-do list. To date the list is as follows:

- replace tires

- change oil and filter

- replace Artificial Horizon ($$$s!!!)

- remove broken hinge wire, replace

It's doubtful that the Native American Summer we're enjoying right now will last long enough to allow that work to be done in relative comfort. But it sure was a nice day to fly!

I thought it would be a good day to take Co-pilot Egg for a short plane ride out to MadCo and environs for a breath of fresh air and a load of new fuel for Papa, then drain the oil for the last oil change of the year.

There's nothing like a plane ride to bring out the natural beauty of a teen aged girl:

Or, you know.... not.

The winds at MadCo were 13 gusting 17, straight out of the south. The only way to have gotten that cross wind any crosser would have been to insult its mother. The landing went OK - I held a bunch of left bank into it and a boot full of right rudder to keep us on the straight and narrow. I thought for a second in the flare that we were going to smack the runway like a spoiled 3 year old at Wal-Mart, but I timed it perfectly and rubbed it on with an unexpected greaser.

I bounced it back at Bolton. Just to keep my streak going, of course.

The Co-pilot was of great assistance when it came time to push the fuel-bloated plane back into the hangar:

While she relaxed, I started to remove the cowls. I didn't, however, finish removing the cowls. If you could pick the absolutely worst place for the long hinge wire that runs along the seam where the top and bottom cowls meet to break, it would be right at the point where the wire would be flush with the first hoop. If that were to happen, you'd have no way in the world short of drilling out all of the rivets that hold the hinge in place on the cowl to get the cowls apart.

Here's what it would look like:

Ask me how I know.

Oh well, it's just one more thing on the to-do list. To date the list is as follows:

- replace tires

- change oil and filter

- replace Artificial Horizon ($$$s!!!)

- remove broken hinge wire, replace

It's doubtful that the Native American Summer we're enjoying right now will last long enough to allow that work to be done in relative comfort. But it sure was a nice day to fly!

Sunday, November 01, 2009

Schmetterling CEO Visit

As a major milestone approaches with the imminent completion of a major aerodynamic surface and flight control, it seemed that it might be a good time for the CEO of our parent company to come for a visit to the production facility. VIP treatment is standard for situations such as these so I took the company plane out to pick him up.

Or, put another way, the weather was gorgeous today and was almost irresistibly beckoning me, but the RV-12 rudder is on the cusp of completion and I really wanted to spend some time doing that. But... there's just no denying the call of a sky that appears as if it may have once or twice heard whispered rumors of these new fangled things called 'clouds' but was believing none of that wild gossip, thank you very much. And calm winds in the forecast as well! Astounding! What better way to kill two birds with one stone (hmm, this seems like a wildly inappropriate time to use that expression) than to fly out to KVES and pick up my Dad and fly him back to Columbus for a shop visit. Sure, it would mean flying him back as well, but seriously, isn't that just a cherry on the sundae?

It was a relaxed morning what with the DST 'found' hour to buffer the time between having a hot cup or two of Vitamin P infused coffee and having to head to the airport for departure. There's no lav in an RV-6, remember? Timing is critical.

The extra hour came from Daylight Savings Time ending later in the year than ever before because our Congress, always eager to flaunt their dominance over us, legislated a seemingly random change in when we shift time. They meddle in so many things anymore that I think a House bill to coerce water into flowing up hill is expected to get voted out of committee next week.

In any event, no one bothered to tell my Garmin 396 of the change of schedule. Try as it might, it just could not find any satellites, my theory being that it was looking at points in space that wouldn't be inhabited by GPS satellites for another hour. Or spots from which satellites had already departed an hour earlier. It could be either - I'm not very good at temporal calculations. If I had to bet, I'd say it was the latter case.

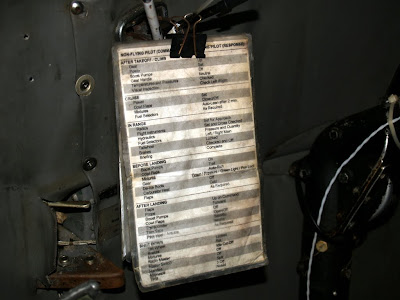

Whatever the cause, buggered if I was going to sit around waiting three months for the clocks to get set back ahead. I'd go without it - I have a nice spare built right into the panel. Although I rarely use it, I do dial in Direct To now and then just to remind myself how. That came in handy today since it was super simple to just dial in KVES and get things going. It's a little less pleasant than the Garmin to use, though:

Always the forgive and forget type, I gave the Garmin another chance. And another, and another, and another. I diddled around with menu pages trying to find a place where I could set the time and, for that matter, the date. It was convinced that it was October 28th. Brilliant little box, but sometimes easily confused. I couldn't find anything that would let me give the unit a temporal foothold on reality, but I did find a way to turn off Daylight Savings Time. I was optimistic about that, but the Garmin stubbornly continued to play the fool:

Finally I stumbled upon a 'Set Location' menu item. Just what I was looking for! You just pick a spot on the map or type in an airport identifier and Bob's your uncle. Well, not so fast: it seems that rather than give it a location as you're pounding through the air at a blistering 3,139 inches per second, you have to be sitting still. I typed in a couple of airports as I flew over or by them, but no luck. As soon as I stopped at KVES, POW!, it found all the satellites it could ever want.

That solved, I got the CEO settled into the right seat and we were off on the trip back to Columbus. The whole VIP thing kind of went sour, though, since I had forgotten to bring the passenger headset. He had to endure the full, unadulterated cacophony of Papa at full gallop. At first I tried cruising at a sedate 2,000 rpm to keep the noise down, but I quickly got bored with that and poured on the coal. After a fuel stop at MadCo, we landed at Bolton and hangared Papa. It was time to visit the shop.

I had the rudder pretty much ready to go for final assembly. Just to provide a complete picture of the work involved, I hadn't deburred the rudder skin yet. A few passes along the Scothbrite wheel made short work of dressing up the edges of the skin and the deburring of the rivet holes is never all that time consuming. It wasn't long at all before we were ready to take the rudder back to the hangar for riveting.

With the construction of the tail kit being well ahead of schedule and the lead time for the next kit (the fuselage) now hovering at somewhere around two months, and in consideration of the all too likely end of year price increase, the discussion turned to whether the order for the fuse kit should be placed. The timing of the tail is looking like I will be ready to assemble the too-big-for-the-shop tail cone by the end of December, just in time for the most inhospitable months of the year for working in the hangar. With the fuse kit on site, I could defer the building of the tail cone until Spring and concentrate on the first stages of the fuselage. Right up until the roll bars go on, the fuse is small enough to assemble in the shop.

As with CEOs everywhere in Corporate America, they need time to think about schedule changes. Deep in thought:

My only fear is that the vertical stab and rudder might be lulling me into over confidence. Maybe the horizontal stab is when this stuff really starts getting hard. I have to say, though, that the RV-12 so far has to be the simplest to build airplane in the world. Seriously, look at this:

The fronts of the rudder skin were already rounded into shape and fit right together with no trouble at all. The skin slid right onto the skeleton and the holes lined up with unconscionable ease. I don't think you can build an RV-9 rudder in just a handful of hours, can you? This thing is amazingly well designed.

We hauled the rudder out to the hangar and pulled about 3/4s of the rivets before we started getting pretty hungry. Also, with the loss of an hour of daylight I had to keep a tight look on the time to make sure I could be back to base before dark. We decided that we'd get started back towards KVES with a lunch stop at Urbana. I always seem to end up at Urbana...

Hey, you know how you always want to impress your Dad? Well, I got a little help with that today from a couple of total strangers.

"See the kind of people that have planes at Bolton? The kind that drive Porsche and Rolls Royce:"

"I just drive a Subaru because I find spectacularly conspicuous consumption like that somehow demeaning." Yeah, that's the ticket.

After lunch, I had him stand next to his artwork for a picture:

The flight from Urbana to KVES went fine, although I wouldn't say it was the best landing of the day. The best was a greaser at Urbana. The rest were so-so. The winds were a bit shifty and three out of the six landings were made with light quartering tailwinds. I'm not saying that's what caused the bad ones, but it could be.

The Sun was getting pretty close to the horizon as I flew back towards home, providing perfect lighting to capture a late Fall tapestry:

Bolton tower had been using runway 4 for most of the day but as I was approaching I heard the tower clear a couple of departures to go out on 22 since they were heading southwest. That meant that I had to land on 22 also, and that meant another landing with a slight tailwind. And, it sucked. I sailed right on past taxiway Alpha 3 and couldn't make the turn off until Alpha 4. That's not a big deal as there was another half a mile of runway after Alpha 4, but it's still a bit below my standard. Eh, it happens.

Once back I finished up the remaining riveting and headed home with a completed rudder:

Next comes the anti-servo tab. I'll 'splain just exactly what that is next time.

Or, put another way, the weather was gorgeous today and was almost irresistibly beckoning me, but the RV-12 rudder is on the cusp of completion and I really wanted to spend some time doing that. But... there's just no denying the call of a sky that appears as if it may have once or twice heard whispered rumors of these new fangled things called 'clouds' but was believing none of that wild gossip, thank you very much. And calm winds in the forecast as well! Astounding! What better way to kill two birds with one stone (hmm, this seems like a wildly inappropriate time to use that expression) than to fly out to KVES and pick up my Dad and fly him back to Columbus for a shop visit. Sure, it would mean flying him back as well, but seriously, isn't that just a cherry on the sundae?

It was a relaxed morning what with the DST 'found' hour to buffer the time between having a hot cup or two of Vitamin P infused coffee and having to head to the airport for departure. There's no lav in an RV-6, remember? Timing is critical.

The extra hour came from Daylight Savings Time ending later in the year than ever before because our Congress, always eager to flaunt their dominance over us, legislated a seemingly random change in when we shift time. They meddle in so many things anymore that I think a House bill to coerce water into flowing up hill is expected to get voted out of committee next week.

In any event, no one bothered to tell my Garmin 396 of the change of schedule. Try as it might, it just could not find any satellites, my theory being that it was looking at points in space that wouldn't be inhabited by GPS satellites for another hour. Or spots from which satellites had already departed an hour earlier. It could be either - I'm not very good at temporal calculations. If I had to bet, I'd say it was the latter case.

Whatever the cause, buggered if I was going to sit around waiting three months for the clocks to get set back ahead. I'd go without it - I have a nice spare built right into the panel. Although I rarely use it, I do dial in Direct To now and then just to remind myself how. That came in handy today since it was super simple to just dial in KVES and get things going. It's a little less pleasant than the Garmin to use, though:

Always the forgive and forget type, I gave the Garmin another chance. And another, and another, and another. I diddled around with menu pages trying to find a place where I could set the time and, for that matter, the date. It was convinced that it was October 28th. Brilliant little box, but sometimes easily confused. I couldn't find anything that would let me give the unit a temporal foothold on reality, but I did find a way to turn off Daylight Savings Time. I was optimistic about that, but the Garmin stubbornly continued to play the fool:

Finally I stumbled upon a 'Set Location' menu item. Just what I was looking for! You just pick a spot on the map or type in an airport identifier and Bob's your uncle. Well, not so fast: it seems that rather than give it a location as you're pounding through the air at a blistering 3,139 inches per second, you have to be sitting still. I typed in a couple of airports as I flew over or by them, but no luck. As soon as I stopped at KVES, POW!, it found all the satellites it could ever want.

That solved, I got the CEO settled into the right seat and we were off on the trip back to Columbus. The whole VIP thing kind of went sour, though, since I had forgotten to bring the passenger headset. He had to endure the full, unadulterated cacophony of Papa at full gallop. At first I tried cruising at a sedate 2,000 rpm to keep the noise down, but I quickly got bored with that and poured on the coal. After a fuel stop at MadCo, we landed at Bolton and hangared Papa. It was time to visit the shop.

I had the rudder pretty much ready to go for final assembly. Just to provide a complete picture of the work involved, I hadn't deburred the rudder skin yet. A few passes along the Scothbrite wheel made short work of dressing up the edges of the skin and the deburring of the rivet holes is never all that time consuming. It wasn't long at all before we were ready to take the rudder back to the hangar for riveting.

With the construction of the tail kit being well ahead of schedule and the lead time for the next kit (the fuselage) now hovering at somewhere around two months, and in consideration of the all too likely end of year price increase, the discussion turned to whether the order for the fuse kit should be placed. The timing of the tail is looking like I will be ready to assemble the too-big-for-the-shop tail cone by the end of December, just in time for the most inhospitable months of the year for working in the hangar. With the fuse kit on site, I could defer the building of the tail cone until Spring and concentrate on the first stages of the fuselage. Right up until the roll bars go on, the fuse is small enough to assemble in the shop.

As with CEOs everywhere in Corporate America, they need time to think about schedule changes. Deep in thought:

My only fear is that the vertical stab and rudder might be lulling me into over confidence. Maybe the horizontal stab is when this stuff really starts getting hard. I have to say, though, that the RV-12 so far has to be the simplest to build airplane in the world. Seriously, look at this:

The fronts of the rudder skin were already rounded into shape and fit right together with no trouble at all. The skin slid right onto the skeleton and the holes lined up with unconscionable ease. I don't think you can build an RV-9 rudder in just a handful of hours, can you? This thing is amazingly well designed.

We hauled the rudder out to the hangar and pulled about 3/4s of the rivets before we started getting pretty hungry. Also, with the loss of an hour of daylight I had to keep a tight look on the time to make sure I could be back to base before dark. We decided that we'd get started back towards KVES with a lunch stop at Urbana. I always seem to end up at Urbana...

Hey, you know how you always want to impress your Dad? Well, I got a little help with that today from a couple of total strangers.

"See the kind of people that have planes at Bolton? The kind that drive Porsche and Rolls Royce:"

"I just drive a Subaru because I find spectacularly conspicuous consumption like that somehow demeaning." Yeah, that's the ticket.

After lunch, I had him stand next to his artwork for a picture:

The flight from Urbana to KVES went fine, although I wouldn't say it was the best landing of the day. The best was a greaser at Urbana. The rest were so-so. The winds were a bit shifty and three out of the six landings were made with light quartering tailwinds. I'm not saying that's what caused the bad ones, but it could be.

The Sun was getting pretty close to the horizon as I flew back towards home, providing perfect lighting to capture a late Fall tapestry:

Bolton tower had been using runway 4 for most of the day but as I was approaching I heard the tower clear a couple of departures to go out on 22 since they were heading southwest. That meant that I had to land on 22 also, and that meant another landing with a slight tailwind. And, it sucked. I sailed right on past taxiway Alpha 3 and couldn't make the turn off until Alpha 4. That's not a big deal as there was another half a mile of runway after Alpha 4, but it's still a bit below my standard. Eh, it happens.

Once back I finished up the remaining riveting and headed home with a completed rudder:

Next comes the anti-servo tab. I'll 'splain just exactly what that is next time.

Sunday, October 25, 2009

Fall Colors

The forecast for this morning called for classic brisk fall weather, cool but clear. With that in mind, Co-pilot Rick and I planned for a trip down to Portsmouth for breakfast, hoping to grab some pictures of the stunning Fall colors we're seeing this year. Unfortunately, the clear morning was running late - we had a light fog at Bolton and Portsmouth was reporting 1/4 mile visibility and 100 foot ceilings. Uh, no. That won't do at all! We postponed our departure and I took the newly found time down to the Schmetterling Aircraft production floor to spend some quality time on the RV-12 tail.

Things at Bolton had cleared up by the newly established departure time of 10:30, but Portsmouth was still reporting horrible conditions. It's an odd airport, though. They will sometimes be reporting conditions that would ground even the bravest horsefly on one end of the runway while the other end is sparkling clear. Worth a look, we figured. With the fallback plan of simply turning around and heading back, we launched ourselves to the south.

It was indeed a pretty Fall day:

At first, anyway. As we approached Portsmouth, it became apparent that we would be eating elsewhere. Still, it was pretty:

Somewhere down under that blanket of clouds lies Portsmouth.

We turned tail and fled back to the clear air of Columbus.

It was a nice day to fly, though, even without accomplishing the breakfast mission. And that left plenty of time in the day to get back to work on the RV-12. I got quite a bit done on that:

Things at Bolton had cleared up by the newly established departure time of 10:30, but Portsmouth was still reporting horrible conditions. It's an odd airport, though. They will sometimes be reporting conditions that would ground even the bravest horsefly on one end of the runway while the other end is sparkling clear. Worth a look, we figured. With the fallback plan of simply turning around and heading back, we launched ourselves to the south.

It was indeed a pretty Fall day:

At first, anyway. As we approached Portsmouth, it became apparent that we would be eating elsewhere. Still, it was pretty:

Somewhere down under that blanket of clouds lies Portsmouth.

We turned tail and fled back to the clear air of Columbus.

It was a nice day to fly, though, even without accomplishing the breakfast mission. And that left plenty of time in the day to get back to work on the RV-12. I got quite a bit done on that:

Sunday, October 18, 2009

Ya still gotta airplane, doncha??

Yes, I know. It must seem as if I've completely forsaken flying my RV-6 and writing to the Papa Golf Chronicles in favor of building an RV-12 (which you have to admit is twice as good as an RV-6, if only numerically) but between the unfavorable weather and a lingering lower back pain, I simply haven't been able to fly. Until today, that is.

While the Weather-out-the-Window™ screamed "Fall Football," it was still adequate for a local trip. More than adequate, really, with crystal clear air and very few clouds hanging around up at the 6,000' level. A little windy, though, with winds out of the north at a brisk 10 gusting 15. Well within my limits, of course, but maybe a little challenging after not having flown for awhile. Just the kind of thing that one could accurately call "good practice," or maybe even "character building."

Bolton was using runway 4 which equated to a roughly 45 degree crosswind from the left. As I lined up for takeoff I reminded myself that a left crosswind accentuates the normal left-turning tendency on takeoff caused by the torque of the engine, so I'd need to be ready with copious amounts of corrective right rudder. I reminded my brain just fine, but as is sometimes the case, my feet didn't get the memo. The first 50 yards or so of alternately swerving towards the grass to the left and then to the right was enough to wake them up, the lazy good-for-nothing slackers.

I could tell almost right away that while the skies looked benign from the ground, in actuality they were going to be pretty bumpy. Why that came as even a slight surprise to me in light of 10 gusting 15 winds is beyond me - I should have expected it. I tried to take a few pictures of my neighborhood as I flew past, but the bumps kept me from getting any in sharp focus. This one was the best I could get:

With no real plan in mind, I headed towards the south east to see how the fall foliage was doing. I took a circle around Mister Sterling (which is what Co-pilot Egg and I call Mt. Sterling after seeing a road sign the misspelled it as Mr. Sterling) and grabbed a shot of the dam:

As I was cruising around (and by "cruising" I mean 2,000 rpm and 120 knots, which both saves gas and gets me acclimated to RV-12 speeds) I noticed that my articial horizon had devloped a bit of a bad attitude. It was, in fact, spinning faster than a White House Press Secretary:

Good thing I don't need it, eh?

I pointed Papa back to the north for the short trip back to Bolton with the idea that I'd approach the field from a position between Bolton and Rickenbacker International. That would set me up for either a right downwind or a direct entry into right base for runway 4, whichever suited the tower controller best at the moment. I called in while still eight miles southeast, hoping for the direct to right base approach. That's right around the time all hell broke loose. A Cessna followed right on my transmission with a call that placed him right in my current area, two more Cessnas were struggling for position on right downwind, and a helicopter wanted to transition the Class D airspace. I was given clearance to enter a right downwind with the stipulation that I should report 3 miles from the field and should also start looking for the Cessna that was somewhere nearby. He was cleared to watch out for me.

As I usually do when confronted with the info that there's a Cessna near me and headed for the same place, I abandoned my RV-12 acclimation training and goosed Papa up to 2,600 rpm. Better to get there first than it is to get there together, I always say. It worked fine for that, but unfortunately caused a wee bit of bother when I reached the 3 mile point:

"Six Papa Golf, three mile right base runway four."

"Six Papa Golf, continue right base, report turning three mile final. Zero Six Bravo, make a 360 from your downwind and report re-entering downwind. [pause] Zero Six Bravo, make a 360 from your downwind and report re-entering downwind. [pause] Zero Six Bravo? [pause] ZERO SIX BRAVO??"

"Tower, Zero Six Bravo, we're on a right base."

Me: cringe! So am I!!

Tower: "Oh. Cessna Two Six Six, make a 360 from your downwind and report re-entering downwind."

By that time, I was ready for the turn onto final, and reported that to the tower.

"Six Papa Golf, cleared to land number two behind the Cessna on right base."

"Tower, Six Papa Golf, traffic not in sight."

"He's now on short final, just over the numbers."

Ah, there he was. Four airplanes stacked up behind him and me on final, and he was landing right.on.the.numbers. If ever there was a situation for intelligently landing a bit long so as to clear the runway more quickly, this was it. I still had a pocket full o' scoot going and was really working hard to get Papa slowed down to 100mph so I could drop the flaps to help get him slowed down even more. Now here's a bit of free advice for you: if you're going to insist on landing right on the numbers and giving yourself a three-quarter mile taxi to the first available taxi way on a day when four airplanes are stacked up behind you, don't slow to a crawl on the runway and taxi at walking speed. Really. Just don't do it.

I had planned on landing long as is my wont when arriving on runway four, but that clearly wasn't in the cards any longer. And getting slowed down in time to land shorter than I had planned required a bit of hard rein on Papa, but I got it done. Even with all that and the gusty winds besides, it was actually a pretty good landing.

At the end of the day I'd say some character got built, especially considering the high degree of hecticity on the landing.

While the Weather-out-the-Window™ screamed "Fall Football," it was still adequate for a local trip. More than adequate, really, with crystal clear air and very few clouds hanging around up at the 6,000' level. A little windy, though, with winds out of the north at a brisk 10 gusting 15. Well within my limits, of course, but maybe a little challenging after not having flown for awhile. Just the kind of thing that one could accurately call "good practice," or maybe even "character building."

Bolton was using runway 4 which equated to a roughly 45 degree crosswind from the left. As I lined up for takeoff I reminded myself that a left crosswind accentuates the normal left-turning tendency on takeoff caused by the torque of the engine, so I'd need to be ready with copious amounts of corrective right rudder. I reminded my brain just fine, but as is sometimes the case, my feet didn't get the memo. The first 50 yards or so of alternately swerving towards the grass to the left and then to the right was enough to wake them up, the lazy good-for-nothing slackers.

I could tell almost right away that while the skies looked benign from the ground, in actuality they were going to be pretty bumpy. Why that came as even a slight surprise to me in light of 10 gusting 15 winds is beyond me - I should have expected it. I tried to take a few pictures of my neighborhood as I flew past, but the bumps kept me from getting any in sharp focus. This one was the best I could get:

With no real plan in mind, I headed towards the south east to see how the fall foliage was doing. I took a circle around Mister Sterling (which is what Co-pilot Egg and I call Mt. Sterling after seeing a road sign the misspelled it as Mr. Sterling) and grabbed a shot of the dam:

As I was cruising around (and by "cruising" I mean 2,000 rpm and 120 knots, which both saves gas and gets me acclimated to RV-12 speeds) I noticed that my articial horizon had devloped a bit of a bad attitude. It was, in fact, spinning faster than a White House Press Secretary:

Good thing I don't need it, eh?

I pointed Papa back to the north for the short trip back to Bolton with the idea that I'd approach the field from a position between Bolton and Rickenbacker International. That would set me up for either a right downwind or a direct entry into right base for runway 4, whichever suited the tower controller best at the moment. I called in while still eight miles southeast, hoping for the direct to right base approach. That's right around the time all hell broke loose. A Cessna followed right on my transmission with a call that placed him right in my current area, two more Cessnas were struggling for position on right downwind, and a helicopter wanted to transition the Class D airspace. I was given clearance to enter a right downwind with the stipulation that I should report 3 miles from the field and should also start looking for the Cessna that was somewhere nearby. He was cleared to watch out for me.

As I usually do when confronted with the info that there's a Cessna near me and headed for the same place, I abandoned my RV-12 acclimation training and goosed Papa up to 2,600 rpm. Better to get there first than it is to get there together, I always say. It worked fine for that, but unfortunately caused a wee bit of bother when I reached the 3 mile point:

"Six Papa Golf, three mile right base runway four."

"Six Papa Golf, continue right base, report turning three mile final. Zero Six Bravo, make a 360 from your downwind and report re-entering downwind. [pause] Zero Six Bravo, make a 360 from your downwind and report re-entering downwind. [pause] Zero Six Bravo? [pause] ZERO SIX BRAVO??"

"Tower, Zero Six Bravo, we're on a right base."

Me: cringe! So am I!!

Tower: "Oh. Cessna Two Six Six, make a 360 from your downwind and report re-entering downwind."

By that time, I was ready for the turn onto final, and reported that to the tower.

"Six Papa Golf, cleared to land number two behind the Cessna on right base."

"Tower, Six Papa Golf, traffic not in sight."

"He's now on short final, just over the numbers."

Ah, there he was. Four airplanes stacked up behind him and me on final, and he was landing right.on.the.numbers. If ever there was a situation for intelligently landing a bit long so as to clear the runway more quickly, this was it. I still had a pocket full o' scoot going and was really working hard to get Papa slowed down to 100mph so I could drop the flaps to help get him slowed down even more. Now here's a bit of free advice for you: if you're going to insist on landing right on the numbers and giving yourself a three-quarter mile taxi to the first available taxi way on a day when four airplanes are stacked up behind you, don't slow to a crawl on the runway and taxi at walking speed. Really. Just don't do it.

I had planned on landing long as is my wont when arriving on runway four, but that clearly wasn't in the cards any longer. And getting slowed down in time to land shorter than I had planned required a bit of hard rein on Papa, but I got it done. Even with all that and the gusty winds besides, it was actually a pretty good landing.

At the end of the day I'd say some character got built, especially considering the high degree of hecticity on the landing.

Monday, October 05, 2009

Driving with Co-pilot Egg, Flying without Co-pilot Rick

I stated on Twitter Friday afternoon that the weekend forecast made it look as if the best flying day for the weekend was going to be.... Monday. And it was.

Sunday dawned with low-ish clouds and 12 knot winds. Flyable if I had somewhere to go, but I've found that Co-pilot Rick's extended vacation in Maui has caused a rather sizable hole to form in the flying schedule. Sure, I can fly without him, but I've grown accustomed to the additional ballast he provides to settle Papa down in choppy air. And without Rick, well, just who would fly the bumpy legs? Me?? No, I'd sooner leave Papa in the hangar and fulfill my fatherly duty to pass down my driving skills to Co-pilot Egg in order to ensure that she will follow in my hereditary footsteps. Which is to say, to make sure she's as obnoxious and aggressive on the road as her dear old dad. But, you gotta crawl before you can walk, and you gotta walk before you can run into other people, so we're still working on the basics.

I've mentioned before that it helps to have a destination in mind (and programmed into the GPS) before departing, so we decided on a road trip to Yellow Springs. And by 'we decided,' I mean 'I dictated'. She wanted to go to the mall. Again. I couldn't take the chance of an honest debate not going my way. Daddy's prerogative.

You may never have heard of Yellow Springs, OH, so I will help you visualize it. Have you ever heard of Berkeley, California? Ok, start with that, but remove the incredibly lush scenery and shrink it down to a postage stamp size. But don't shrink the prevalent political viewpoints. There ya go: Yellow Springs. It's where Ohio hippies that can't afford to move to Berkeley live. Me, I'm all about exposing Egg to diverse viewpoints and encouraging her to keep an open mind. Well, an open mind to my explanations about why they're completely wrong about literally everything, of course, but yeah, an open mind.

We took rural country roads on the way there and it was, for the most part, a relatively uneventful drive. By 'relatively' I mean that I only slapped my foot on the illusory passenger-side brake pedal a half dozen times. As opposed to doing that a handful of times while trying to avoid a wreck just getting out of the neighborhood, as I have in recent memory. She's definitely showing progress. Daddy is proud!

As much as learning to drive has been a learning experience for her, it has been for me as well. Seriously, there's not much to do while driving through Central Ohio other than talk. And as we've been going to places, I learn more and more about what she knows that I didn't think she knew. You're probably thinking that I'm talking about the swear words I use when she scares me, and she has surely learned a few of those as we drive, but that's not really what I'm getting at. She already knew all of them (and more!) from school. Here, I'll provide an example of what I mean:

The Import House. Sounds benign, right? Well, I forgot where we were. In we went.

"Hey, Dad, this place is full of bongs!"

You know how a series of thoughts can pass through your mind in the blink of an eye? Well, here's how mine went:

Uh-oh.

Act cool.

Hey, wait a minute! She knows what a bong is???

How did that happen??

Omagawd, I'm getting soooo old.

She then said, "How is this even legal?"

"Ah, there you go: Daddy's little Republican!"

So, yeah, we didn't spend much time or any money in The Import House.

But you know what she had never actually seen before?

This:

Go figure.

So, off to the Comic Book store, filled with visions of Archie & Jughead, Richie Rich the Poor Little Rich Boy, and maybe a super hero or two.

Sigh:

As I was thinking that it might be time to beat another hasty and ignominious retreat, I heard her talking to The Comic Book Guy:

"Do you have any DeathNote," she asked.

"Whhaaaaatttttt??? I thought. What the heck is Death Note???

Japanese "comic" books. Manga, in the vernacular.